Additives

Viscosity Index Improver

One of the main functions of the lubricant is to reduce friction and, consequently, heating and wear between moving parts. To achieve this, the lubricant forms a film to separate the surfaces and minimize metal-to-metal contact. The thickness of the film is a function of viscosity.

Viscosity can be defined as the internal resistance to flow. Therefore, the greater the resistance to flow, the greater the viscosity of the oil. The viscosity of liquids decreases with increasing temperature and at high temperatures it can drop to a very low level, which will cause it to lose the ability to maintain a satisfactory lubricating film on the surfaces. In order to know how much the temperature affects the viscosity of a given lubricant, we use the viscosity index as a common measure to define these viscosity-temperature characteristics in the lubricants.

According to ASTM D-2770: Standard Practice for Calculating the Viscosity Index of the Kinematic Viscosity at 40 ° C and 100 ° C, the viscosity index is defined as “an arbitrary number used to characterize the variation in the kinematic viscosity of a oil product with temperature. For oils with similar kinematic viscosity, the higher the viscosity index, the less the effect of temperature on kinematic viscosity ”.

To ensure that the lubricant performs better at elevated temperatures, viscosity index (VI) enhancing additives are added. VI improvers are performance additives that make it possible to formulate multiple grade oils. They are high molecular weight polymeric chemical compounds that are added to low viscosity oils to improve their high temperature lubrication characteristics. This is a practical way to extend the operating range of mineral oils to higher temperatures, without adversely affecting their low temperature fluidity. At low temperatures, the polymer molecules occupy a small volume and therefore have minimal association with the oil. At high temperatures, however, the situation is reversed because the polymer chains extend or expand. This increases the association of the polymer with the oil due to an increase in its surface area. The result is an effective increase in viscosity. Another way of describing this phenomenon is that, at higher temperatures, the polymer becomes more soluble, causing an increase in viscosity.

Viscosity modifiers find great use in engine and gear oils of various classes, transmission fluids, power steering fluids, greases and some hydraulic fluids.

Temporary Viscosity Loss

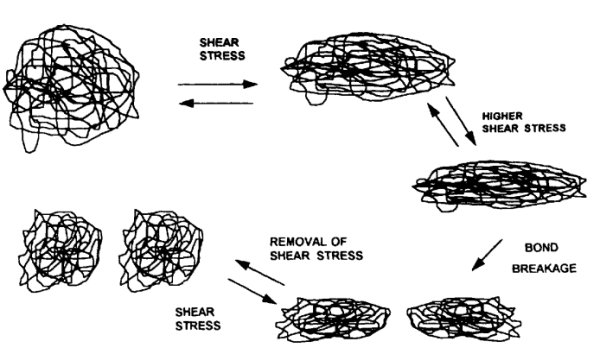

One effect that the polymer has on the oil is a change in viscosity as a function of the shear ratio.

Hydrocarbon molecules or molecular aggregates that make up the oil experience shear forces while in a container or during flow. These forces can cause a degradation of these molecules, leading to loss of viscosity. Pure mineral oils are unaffected by these shear forces and retain their viscosity. However, shear forces can significantly affect the viscosity of finished lubricants. Finished lubricants generally contain additives that lead to structural viscosity, called apparent viscosity, which decreases progressively under the influence of shear. This apparent loss of viscosity results from the deformation of the spherical shape of the polymer molecules. This loss of viscosity is temporary, the fluid regains its original viscosity when the shear rate is reduced and the polymer molecules return to their original forms.

Permanent Viscosity Loss

The same shear forces, which cause temporary loss of viscosity, can be strong enough to cause permanent loss of viscosity. This is due to the rupture of the polymer molecule, forming smaller molecules and, consequently, losing effectiveness.

This can happen in several areas of the equipment, for example, between piston rings and a cylinder wall, between the camshaft and follower in the valve train of an engine, between gear teeth or through the pressure relief valve of a hydraulic system.

The table below shows some typical VI values. It is worth noting that synthetic oils have higher VIs than mineral oils. This is a typical characteristic of synthetic products.

| Lubricant | Test | Method | Typical Value |

|---|---|---|---|

| Havoline Extra SAE 15W40 SS | Visc.40°C | D-445 | 108.3 |

| Visc.100°C | D-445 | 14,4 | |

| VI | D-2270 | 135 | |

| MaxLife Motor Oil SAE 15W40 | Visc.40°C | D-445 | 108.0 |

| Visc.100°C | D-445 | 14 | |

| VI | D-2270 | 130 | |

| Shell Rotella T5 15W40 CK-4 | Visc.40°C | D-445 | 111.2 |

| Visc.100°C | D-445 | 14.9 | |

| VI | D-2270 | 138 | |

| Brutus Performance 15W40 CJ-4 | Visc.40°C | D-445 | 109,7 |

| Visc.100°C | D-445 | 14,52 | |

| VI | D-2270 | 136 | |

| Delvac MX 15W40 CI-4 | Visc.40°C | D-445 | 108,0 |

| Visc.100°C | D-445 | 14,4 | |

| VI | D-2270 | 136 | |

| Delvac MX ESP 15W40 CK-4 | Visc.40°C | D-445 | 109,0 |

| Visc.100°C | D-445 | 14,1 | |

| VI | D-2270 | 130 | |

| Rimula R6MS 10W40 CI-4 Sint | Visc.40°C | D-445 | 90,0 |

| Visc.100°C | D-445 | 13,6 | |

| VI | D-2270 | 153 | |

| Extremo HD 5W30 Sint | Visc.40°C | D-445 | 72,7 |

| Visc.100°C | D-445 | 11,1 | |

| VI | D-2270 | 165 |

TIP

Viscosity Index CalculatorLet your comment here

All fields must be filled

2023-04-01 19:39:20

791781

Spoodia@barrettmail.xyz