Lubrication

Lubrication Fundamentals: Lubrication

When we talk about lubrication, we usually talk about liquid lubrication, that is, using lubricating oil, which is usually a mixture of base oils and additives that perform various functions. The lubrication efficiency of an oil depends not only on its properties, such as composition, consistency, flow properties and surface activity, but also on the needs of the tribological system . Lubrication regimes are defined mainly considering these needs. The factors that are considered include the geometry of the contact surfaces, their texture and roughness, the nature of the rolling versus sliding contact, the contact load, ambient pressure and temperature, the environmental conditions, material composition and the properties of the surface layers . Lubrication efficiency is measured by the thickness of the film, the ability to handle the load capacity and the friction coefficient.

Effect of Film Thickness on Friction

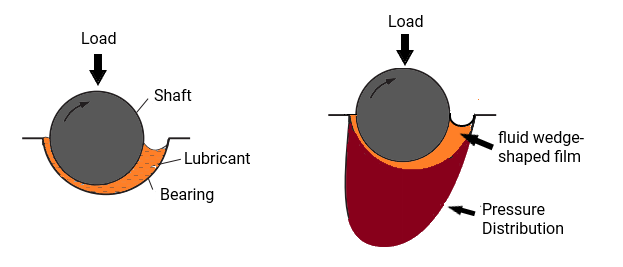

The modern period of lubrication began with the work of Osborne Reynolds (1842-1912). Reynold's research was related to shafts rotating in bearings. When a lubricant was applied to the shaft, Reynolds found that a rotating shaft pulled a converging lubricant wedge between the shaft and the bearing. He also noticed that as the axis gained speed, the liquid flowed between the two surfaces at a higher rate. This is because the lubricant is viscous and produces a liquid pressure in the lubricant wedge that is sufficient to keep the two surfaces separate. Ideally, Reynolds showed that the pressure of the liquid was large enough to prevent direct contact between the metal surfaces (Figure 1).

Stribeck Diagram

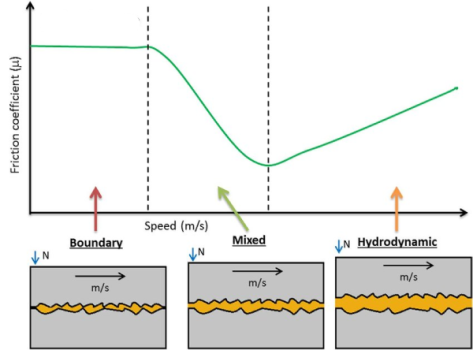

As mentioned, the main functions of a lubricant are to minimize friction between the surfaces in contact, avoid wear and remove frictional heat. The tribological parameters that generally define a lubrication environment are the friction , the lubricant viscosity and the speed and load of the equipment. The relationship between the friction coefficient and the thickness of the oil film with the viscosity "Z" of the lubricant, speed "N" of the equipment and load of the equipment, or pressure "P", are presented graphically by the Stribeck curve (Figure 2 ). The ZN / P ratio is directly related to the thickness of the oil film, but inversely to the friction coefficient. This implies that the high viscosity "Z" of the lubricant, the high speed "N" of the equipment and the low load of the equipment "P" will allow the formation of a thick film of lubricant and, therefore, the equipment will encounter little or no friction. On the other hand, the low viscosity of the lubricant, the low speed of the equipment and the high load of the equipment will create a situation in which the thickness of the film will be inadequate and the equipment will encounter high friction, as shown in figure 2.

Lubrication Regimens

Fluid Film Lubrication

Fluid film lubrication, also known as hydrodynamic lubrication, is the most desirable type of lubrication. This type of lubrication depends on the lubricant's viscosity and is effective only when the load in the contact zone is low. In these circumstances, the sliding or rolling surfaces are separated by a lubricating film several times greater than the thickness of the surface roughness and the surfaces are completely separated. Lubrication of the bearings and most parts of the internal combustion engine undergo fluid film lubrication.

Another type of hydrodynamic lubrication, known as elastohydrodynamic lubrication, or EHD, typically occurs in roller and ball bearings, cams and gears. In this type of lubrication, the load is high enough to cause elastic deformation of the surfaces, the lubricant is exposed to high contact pressures and undergoes a great increase in viscosity.

Boundary Lubrication

Boundary lubrication represents the opposite end of hydrodynamic lubrication. Under this type of lubrication, high loads and very low speeds produce extreme pressures that can lead to a lack of effective lubrication. The film thickness is very small and metal-to-metal contact occurs. The presence of anti-wear additives is necessary to ensure the formation of a limit film and performance.

Mixed Lubrication

Mixed lubrication is between the two extremes mentioned above and contains both characteristics. The surfaces are close enough for contact between surfaces to occur occasionally.

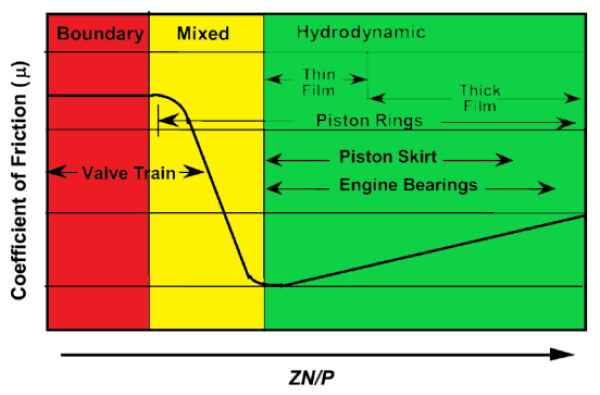

Figure 3 below shows the lubrication regimes existing in combustion engines. It helps us to assess where the highest incidence of wear would be most likely under normal operating conditions.

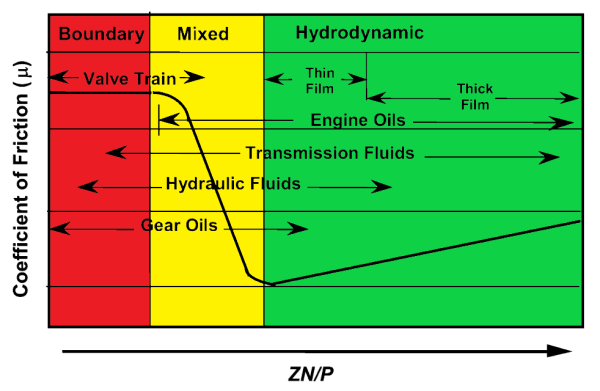

Figure 4 shows the lubrication regimes to which the lubricants applied in the automotive line are subject.

Referências Bibliográficas

Rizvi, S.Q.A. A Comprehensive review of lubricant chemistry, technology, selection, and design. PA. ASTM. 2009

Let your comment here!!!

All fields must be filled

>2024-07-30 06:01:44

ernautdatheand6c0+2606k4srs2vh@gmail.com

ernautdatheand6c0+2606k4srs2vh@gmail.com

2024-07-09 17:27:06

ernautdatheand6c0+2606k2u956qn@gmail.com

ernautdatheand6c0+2606k2u956qn@gmail.com

2024-06-28 00:19:28

medranostarckuzz8n0+2606k4ms61bb@gmail.com

medranostarckuzz8n0+2606k4ms61bb@gmail.com

2024-06-17 07:12:06

medranostarckuzz8n0+2606k3m34n90@gmail.com

medranostarckuzz8n0+2606k3m34n90@gmail.com

2024-06-05 00:47:31

flagstoneveneydel2q9+osp07l56k7@gmail.com

flagstoneveneydel2q9+osp07l56k7@gmail.com

2024-05-28 22:56:09

sorgelakhanakp9z5+osp2f50rs8@gmail.com

sorgelakhanakp9z5+osp2f50rs8@gmail.com

2024-05-21 21:18:39

schermerdusenberycmp5p8+osp1q9ehvu@gmail.com

schermerdusenberycmp5p8+osp1q9ehvu@gmail.com

2022-01-25 13:01:21

ailton gomes

ailtongomes04913@gmail.com